1.– Steel structure of machine's frame & safety acrylic door constructed to ensure operators safety.

2.– Setting & operating from the interface to reveal the unusual situation of the machine.

3.– Synchronous adjustment design makes machine to be easier operation without professional technician.

4.– Only few minutes change over time to fit different size of container.

5.– Simple & quick structure of label unwinds for time saving and ensure safety.

6.– Clear sight of label unwind system to avoid mistakes happen easily from operators.

7.– Single driving wheel design keep the stability of mandrel inserting movement.

8.– Saving the cost by flexible accessory design.

9.– To meet customize inserting requirement by offering various accessory with the machine.

XYL-060 |

|

| Power Source : | 3P / 220V ~ 415V |

| Production rate : | 60 BPM ( label length 100 mm) |

| Range of bottle diameter : | Ø25 ~ Ø125 |

| Label insertion length : | 35 mm ~ 180 mm |

| Range of label thickness : | 0.035 ~ 0.08 mm |

| Material : | PVC, PET, OPS |

| Total Power : | 2.5 KW |

| Machine dimensions ( L × W × H ): | 800 × 1032 × 1850 mm |

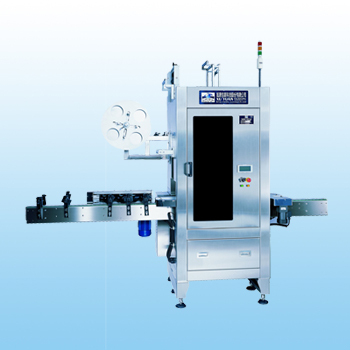

1.– Machine constructed by stainless steel. Comply with safetyregulation. Single machine structure ensures convenient installation.

2.– Modular design for quick changeover.

3.– Interface touch controller for user-friendly operation.

4.– Only need minor adjustment to fit different inserting container.

5.– Ground sleeve reel system bring the safe and easy way of changing reel.

6.– High speed splicing system enables reel change without stop the machine. Improve line productivity.

7.– Machine design can fit the label height up to 300mm and above.

XYL-250L |

|

| Power source : | 3P/ 220V~ 415V |

| Production rate : | 250BPM(label length 180mm) |

| Range of bottle diameter: | Ø25 ~ Ø125 |

| Label insertion length: | 25mm ~ 220mm |

| Range of label thickness : | 0.035mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 4KW |

| Machine dimension(L×W×H) : | 1190 × 980 × 2100mm |

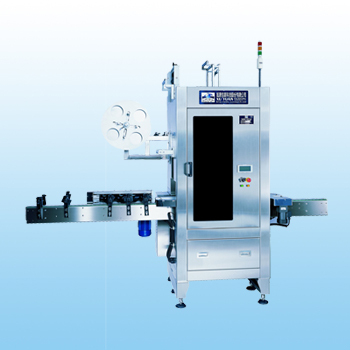

1.– Machine constructed by stainless steel with especially and luxurious appearance. Conform to safety regulation. Single machine structure ensures convenient installation.

2.- Modular design for quick changeover.

3.– All adjustable modular design by transmission type for easy operation and fast adjustment.

4.– The accurate gear wheel design for driver system to stable the transmition speed and limit the label height within (+/-) 1mm tolerance.

5.– Using supersonic sensor to detect sleeve and with spring tension controller system for ensuring the feeding sleeve steady.

6.– The interface with large screen touch controller for user-friendly operation.

7.– Machine design can fit the label height up to 300mm and above.

XYL-250S |

|

| Power source : | 3P/ 220V~ 415V |

| Production rate : | 250BPM(label length 180mm) |

| Range of bottle diameter: | Ø25 ~ Ø125 |

| Label insertion length: | 25mm ~ 220mm |

| Range of label thickness : | 0.035mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Powerr : | 4KW |

| Machine dimension(L×W×H) : | 1190 × 980 × 2100mm |

1.– Overall coverage frame to meet safety operation regulation.

2.– Modular designed for quick change over.

3.– Synchronous adjustment design makes machine to be easier operation without professional technician.

4.– Simple & quick structure of label unwinds for time saving and ensure safety.

5.– Interface touch controller for easy adjustment.

6.– To meet customize inserting requirement by offering various accessory with the machine.

XYL - 100 |

|

| Power source : | 3P/220V~415V |

| Production rate : | BPM100 (label length 100mm) |

| Range of bottle diameter: | Ø25 ~ Ø125 |

| Label insertion length: | 25mm ~ 180mm |

| Range of label thickness : | 0.035mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 2.5KW |

| Machine dimension(L×W×H) : | 900 × 980 × 1850mm |

1.– Machine constructed by stainless steel. Comply with safety regulations. Simplex machine structure ensures convenient installation.

2.– Modular design for quick changeover.

3.– Interface touch controller for user-friendly operation.

4.– Only need minor adjustment to fit different inserting container.

5.– Simple & quick structure of label unwinds for time saving and ensure safety.

6.– Easy connect to labeling machine or filling machine for saving the production line space.

7.– Easy portable to meet whole production line requirement.

8.– CE Approved.

XYC-300 |

|

| Power source : | 3P/ 220V~ 440V |

| Production rate : | 300BPM(label length 100mm) |

| Range of CAP diameter: | Ø25 ~ Ø50 |

| Label insertion length: | 25mm ~ 50mm |

| Range of label thickness : | 0.04mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 3KW |

| Machine dimension(L×W×H) : | 660 × 800 × 1250mm |

XYC-600 |

|

| Power source : | 3P/ 220V~ 440V |

| Production rate : | 600BPM(label length 100mm) |

| Range of CAP diameter: | Ø25 ~ Ø50 |

| Label insertion length: | 25mm ~ 50mm |

| Range of label thickness : | 0.04mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 5KW |

| Machine dimension(L×W×H) : | 660 × 800 × 1250mm |

1.– Machine for cap seal standard. Compact, lightweight design is suitable for conveyor belt installation.

2.– Machine constructed by stainless steel. Comply with safety regulation. Simplex machine structure ensures convenient installation.

3.– Modular design for quick changeover and easy replacement.

4.– Interface touch controller for user-friendly operation.

5.– Simply change mandrel design to fit different container size.

6.– Special cutter designed to make easy TAP hold to tear cap sleeve.

XYC-150 |

|

| Power source : | 3P/ 220V~ 415V |

| Production rate : | 150BPM(label length 50mm) |

| Range of bottle diameter: | Ø25 ~ Ø65 |

| Label insertion length: | 25mm ~ 100mm |

| Range of label thickness : | 0.04mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 1KW |

| Machine dimension(L×W×H) : | 830 × 850 × 2070mm |

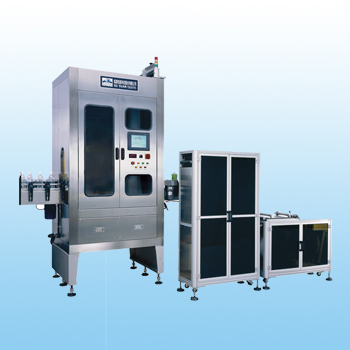

1.– Meeting high speed filling machine requirement 72000BPH.

2.– Twin inserting application in single machine structure , can prevent machine brake down and save production line space.

3.– Machine constructed by stainless steel. Followed by safety regulation. Simplex machine structure ensures convenient installation.

4.– Modular desing for quick changeover.

5.– Interface touch controller for user-friendly operation.

6.– To change new product to another, it takes only minor adjustment.

7.– Using multi-Axis Controller and synchronous design to reach the high speed accurately.

8.– Provide the suitable label feeding system to match different production line requirement.

9.– Machine design can fit the label height up to 300mm and above.

XYL-1200 |

|

| Power source : | 3P / 220V ~ 415V |

| Production rate : | 1200BPM(label length 180mm) |

| Range of bottle diameter : | Ø25 ~ Ø130 |

| Label insertion length : | 25 mm ~ 220 mm |

| Range of label thickness : | 0.035 ~ 0.08 mm |

| Material : | PVC, PET, OPS |

| Total Power : | 30 KW |

| Machine dimensions ( L × W × H ): | 2600 × 1430 × 2250 mm |

1.– Machine design with the " Innovated Single Inserting Head" to reach 800bpm on 180mm label height sleeve.

2.– Machine constructed by stainless steel with especially and luxurious appearance. Comply with safety regulation. Single machine structure ensures convenient installation.

3.– Standardization and modularity design for change over convenience and quickly during repair and maintenance.

4.– Driver system with precision gear design, speed stably to reach label height at +/-1mm tolerance.

5.– Ultrasonic sensor response with sliding system, collocate with spring tension control system for sleeve more stably.

6.– Mechanism adjusts by a precision instrument design, can adjust to the setting location wanted easily and accurately when change the product dimension or product line.

7.– Label change design by roll up accumulation system. According to the length of the label, the machine no stop for sleeve continually with 90-100 minutes during high speed operation.

8.– Axles control design as principle and follows the mode automatically to reach the high speed accurately.

9.– Greatly colorful interface control panel as master control for all operations and control sets, close to humanization.

10.– Machine could be special designed according to label length max to 300mm above.

XYL-800 |

|

| Power source : | 3P/ 220V~ 415V |

| Production rate : | 800BPM(label length 180mm) |

| Range of bottle diameter: | Ø25 ~ Ø130 |

| Label insertion length: | 25mm ~ 220mm |

| Range of label thickness : | 0.035mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 15KW |

| Machine dimension(L×W×H) : | 1700 × 1375 × 2100mm |

1.– Machine constructed by stainless steel. Comply with safety regulation. Simplex machine structure ensures convenient installation.

2.– Modular desing for quick changover.

3.– Interface touch controller for user-friendly operation.

4.– To change new product to another, it takes only minor adjustment.

5.– Multi-AxisController and synchronous design to reach the high speed accurately.

6.– The design is follow to the production line requirments for providing the suitable label feeding system.

7.– Machine could be special designed according to label length max to 300mm above.

XYL-600S |

|

| Power Source : | 3P / 220V ~ 415V |

| Production Rate : | 600 BPM ( label length 180 mm) |

| Range of bottle diameter : | Ø25 ~ Ø130 |

| Label insertion length : | 25 mm ~ 220 mm |

| Range of label thickness: | 0.035 ~ 0.08 mm |

| Material : | PVC, PET, OPS |

| Total Power : | 12 KW |

| Machine dimensions ( L × W × H ): | 1190 × 1250 × 2100 mm |

1.– Machine design by "single body structure with double inserting head", conform to cap labeling with body labeling requirements in the meantime by speed 600 bottles per minute.

2.– Machine constructed by stainless steel with especially and luxurious appearance. Comply with safety regulation. Single machine structure ensures convenient installation.

3.– Standardization and modularity design for change over convenience and quickly during repair and maintenance.

4.– Bipartite sleeve supply system with double reel alternating design, to reduce the time of sleeve continuously and improve production efficiency.

5.– Interface controller design can operation with production both in the meantime or single-handed.

6.– To short with connect production line space design, one production line to collocate with one shrink tunnel can be conformed to production requirement.

7.– Colorful interface touch controller has highly sensitive operation by collocate with High Performance motion control system.

8.– Knife plate and drive are using high level drive system and server motor for motion with stable and accurately.

9.– Machine design can fit the label height up to 300mm and above.

XYLC-600 |

|

| Power Source : | 3P/ 220V~ 415V |

| Production rate : | 600BPM(label length 180mm) |

| Range of bottle diameter: | Ø25 ~ Ø125 |

| Label insertion length: | 25mm ~ 220mm |

| Range of label thickness : | 0.035mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 9KW |

| Machine dimension(L×W×H) : | 2600 × 1330 × 2100mm |

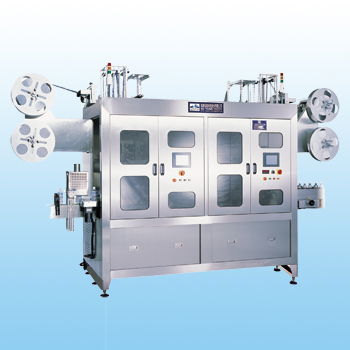

1.– Machine design by "single body structure with double inserting head", conform to cap labeling with body labeling requirements in the meantime by speed 400 bottles per minute.

2.– Machine constructed by stainless steel with especially and luxurious appearance. Comply with safety regulation. Single machine structure ensures convenient installation.

3.– Standardization and modularity design for change over convenience and quickly during repair and maintenance.

4.– Bipartite sleeve supply system with double reel alternating design, to reduce the time of sleeve continuously and improve production efficiency.

5.– Double interface controller design can operation with production both in the meantime or single-handed.

6.– To short with connect production line space design, one production line to collocate with one shrink tunnel can be conformed to production requirement.

7.– Colorful interface touch controller has highly sensitive operation by collocate with High Performance Mitsubishi PLC controller.

8.– Knife plate and drive are using high level drive system and server motor for motion with stable and accurately.

9.– Machine design can fit the label height up to 300mm and above.

XYLC-400 |

|

| Power source : | 3P/ 220V~ 415V |

| Production rate : | 400BPM(label length 180mm) |

| Range of bottle diameter: | Ø25 ~ Ø125 |

| Label insertion length: | 25mm ~ 220mm |

| Range of label thickness : | 0.035mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 9KW |

| Machine dimension(L×W×H) : | 2600 × 1330 × 2100mm |

1.– Machine constructed by stainless steel with especially and luxurious appearance. Conform to safety regulation. Single machine structure ensures convenient installation.

2.– Modular design for quick changeover.

3.– New accumulating label system use precision roller design with splicing system. One minute accumulating period to achieve the production speed up to 450 bpm on100 mm label height.

4.– High speed splicing system enables reel change without machine to stop. Improve line productivity.

5.– All adjustable modular parts require simple operation and minor adjustment.

6.– The accurate gear wheel design for driver system to stable the transmition speed and limit the label height within (+/-) 1mm tolerance.

7.– Using supersonic sensor to detect sleeve with the spring tension controller system to ensure feeding sleeve steady.

8.– Colorful interface touch controller for friendly user operation.

9.– Machine design can fit the label height up to 300mm and above.

XYL-450L |

|

| Power source : | 3P/ 220V~ 415V |

| Production rate : | 450BPM(label length 180mm) |

| Range of bottle diameter: | Ø25 ~ Ø125 |

| Label insertion length: | 25mm ~ 220mm |

| Range of label thickness : | 0.035mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 5KW |

| Machine dimension(L×W×H) : | 1190 × 1250 × 2100mm |

1.– Machine constructed by stainless steel with especially and luxurious appearance. Conform to safety regulation. Single machine structure ensures convenient installation.

2.– Modular design for quick changeover.

3.– All adjustable modular parts require simple operation and minor adjustment.

4.– The accurate gear wheel design for driver system to stable the transmition speed and limit the label height within (+/-) 1mm tolerance.

5.– Using supersonic sensor to detect sleeve with spring tension controller system to ensure feeding sleeve steady.

6.– Colorful interface touch controller for friendly user operation.

7.– Machine design can fit the label height up to 300mm and above.

XYL-450S |

|

| Power source : | 3P/ 220V~ 415V |

| Production rate : | 450BPM(label length 180mm) |

| Range of bottle diameter: | Ø25 ~ Ø125 |

| Label insertion length: | 25mm ~ 220mm |

| Range of label thickness : | 0.035mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 5KW |

| Machine dimension(L×W×H) : | 1190 × 1250 × 2100mm |

1.– Machine constructed by stainless steel with especialIy and luxurious appearance. Comply with safety regulation. Single macnine structure ensures convenient installaticn.

2.– Modular design for quick changeover.

3.– New accumulating label system use precision roller design with sliding system. One minute accumulating time for achieve productin speed 350 bottles per minute with 100mm label height.

4.– Hight speed splicing system enables reel change without stopping the machine. Improve line productivity.

5.– All adjustable modular with synchronous design, minor operation and adjustment.

6.– The accurate gear wheel design for driver system to stable the transmition speed and limit the label height within (+/-) 1mm tolerance.

7.– Using supersonic sensor to detect sleeve with spring tension controller system to ensure feeding sleeve steady.

8.– Sleeve guider section with sliding system for sleeve supply steadily.

9.– Colorful interface touch controller has highly sensitive operation by collocate with High Performance Mitsubishi PLC controller.

10.– Machine design can fit the label height up to 300mm and above.

XYL-350L |

|

| Power source : | 3P/ 220V~ 415V |

| Production rate : | 350BPM(label length 180mm) |

| Range of bottle diameter: | Ø25 ~ Ø125 |

| Label insertion length: | 25mm ~ 220mm |

| Range of label thickness : | 0.035mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 5KW |

| Machine dimension(L×W×H) : | 1190 × 1250 × 2100mm |

1.– Machine constructed by stainless steel with especially and luxurious appearance. Conform to safety regulation. Single machine structure ensures convenient installation.

2.– Modular design for quick changeover.

3.– All adjustable modular with synchronous design, minor operation and adjustment.

4.– The accurate gear wheel design for driver system to stable the transmition speed and limit the label height within (+/-) 1mm tolerance.

5.– Using supersonic sensor to detect sleeve with spring tension controller system for ensuring the feeding sleeve steady.

6.– Sleeve guider section with sliding system for sleeve supply steadily.

7.– Colorful interface touch controller has highly sensitive operation by collocate with High Performance Mitsubishi PLC controller.

8.– Machine design can fit the label height up to 300mm and above.

XYL-350S |

|

| Power source : | 3P/ 220V~ 415V |

| Production rate : | 350BPM(label length 180mm) |

| Range of bottle diameter: | Ø25 ~ Ø125 |

| Label insertion length: | 25mm ~ 220mm |

| Range of label thickness : | 0.035mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 5KW |

| Machine dimension(L×W×H) : | 1190 × 1250 × 2100mm |

1.– Machine construction by stainless steel in single structure for easy installation.

2.– Modular design for easy and quick changeover.

3.– Automatic label splicing system without machine stop.

4.– New design of mandrel fix with air cylinder, easy change and adjust.

5.– Ultrasonic sensor response with sliding system, collocate with spring tension control system for sleeve more stable.

6.– Colorful interface touch controller for friendly use operation.

7.– LED display in front of machine, to understand the machine's status quickly and easily.

8.– Database build by HMI to maintain an easy operation.

9.– Machine could be special designed according to label length up to 300mm or above.

| XYL-600AJ | |

| Power source : | 3P / 220V ~ 415V |

| Production rate : | 600 BPM ( label length 180 mm) |

| Range of bottle diameter : | Ø25 ~ Ø125 |

| Label insertion length : | 25 mm ~ 220 mm |

| Range of label thickness : | 0.035 ~ 0.08 mm |

| Material : | PVC, PET, OPS |

| Total Power : | 16 KW |

| Machine dimensions ( L × W × H ): | 1190 × 1250 × 2100 mm |

1.– Automatic Horizontal Shrinkable Label Inserting Machine position design by un-stand products. Product dimension from minimum 7mmto maximum 20mm.

2.– Automatic Horizontal Shrinkable Label Inserting Machine constructed by stainless steel. Comply with safety regulation. Simplex machine structure ensures convenient installation.

3.– Automatic Horizontal Shrinkable Label Inserting Machine with modular design for quick changeover.

4.– Automatic Horizontal Shrinkable Label Inserting Machine with interface touch controller for use-friendly operation.

5.– High-accuracy rotation position system. Inserting label exactness is up to 5/10000.

6.– Special cutter set design. Size of the diameter of the products in the specification. Do not need to change the knife.

7.– Axles control design as principle and follows the mode automatically to reach the high speed accurately.

8.– Add optional equipment according to the customer's demand of the packing.

XYH-250 |

|

| Power source : | 3P/220V~415V |

| Production rate : | 250 BPM (label length 100mm) |

| Range of bottle diameter: | Ø7 ~ Ø20 |

| Label insertion length: | 30mm ~ 200mm |

| Range of label thickness : | 0.05mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Main motor : | 6KW |

| Machine dimension(L×W×H) : | 1850 × 900 × 1750mm |

1.– Machine designed by linear type, including the Hot melt glue, Roll-fed label, and Servo motor control.

2.– The appearance of the OPP Labeling Machine is constructed by stainless steel. Strong base frame structure to prevent vibration and noise absorbing. Simplex machine structure ensures convenient installation.

3.– Modular design for quick and convenient changeover.

4.– Colorful interface touch panel for user-friendly operation. All parameter set in HMI.

5.– High-accuracy labeling position system. The stick label upper and lower tolerance within +/-1 mm.

6.– Special cutter set design. Cutting label smoothly and accurately at different speed. Modular design for quick, convenient changeover and adjustment.

7.– Axles control design as principle and follows the mode automatically to reach the high speed accurately.

8.– Add optional equipment according to the customer's demand and request of the packing.

XYM-300 |

|

| Machine Size : | 3700mm(L) x 1500mm(W) x 1850mm(H) |

| Desk Height Adjustable: | +/- 100mm |

| Label Length(max/min): | 280/180 |

| Container dia max: | 90mm(Product Diameter : 50~90) |

| CPH Round : | 18000 Bottle/hr |

| Power Supply: | 24 KVA |

| Driver Motor : | 5 KW |

| Control Voltage: | 24 VDC |

| Main Voltage: | According to Customer’s |

| Air Consumption: | 7.5m2/H |

| Operating Pressure: | 5Bar |

1.– Speciality designed for larger container. The container dimension could reach up to 215mm..

2.– Machine constructed by stainless steel. Follow by safety regulation. Simplex machine structure to ensures convenient installation.

3.– Modular design for quick changeover.

4.– Interface touch controller for user-friendly operation.

5.– Only need minor adjustment to fit different size of container.

6.– Special cutter design and simple spare parts changeover for reaching different container diameter.

7.– Customize design to meet different requirements.

XYL-100L |

|

| Power source : | 3P/220V~415V |

| Production rate : | 100 BPM (label length 100mm) |

| Range of bottle diameter: | Ø120 ~ Ø215 |

| Label insertion length: | 75mm ~ 250mm |

| Range of label thickness : | 0.05mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Main motor : | 2.5KW |

| Machine dimension(L×W×H) : | 1000 × 1160 × 2950mm |

1.– Single machine structure ensures change over.

2.- Simple & quick structure of label unwinds for time saving and ensures the operation safety.

3.– Driver delivery design to cooperate with synchronous feeding mechanism can improve the accuracy of label inserting.

4.– Completely function of interface touch controller for user-friendly operation.

5.– To meet customize inserting requirement by offering various accessory with the machine.

6.– Machine design can fit the label height up to 300mm and above.

XYL-200 |

|

| Power source : | 3P/220V~415V |

| Production rate : | 200 BPM(label length 100mm) |

| Range of bottle diameter: | Ø25 ~ Ø125 |

| Label insertion length: | 25mm ~ 220mm |

| Range of label thickness : | 0.035mm ~ 0.08mm |

| Material: | PVC, PET, OPS |

| Total Power : | 4KW |

| Machine dimension(L×W×H) : | 900 × 860 × 2100mm |